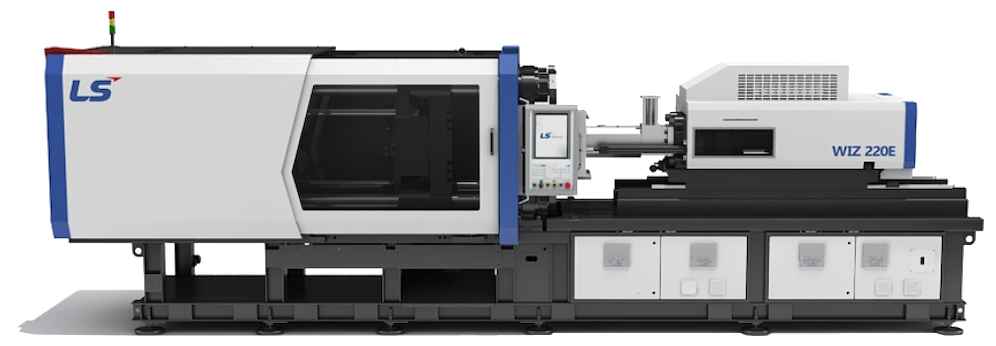

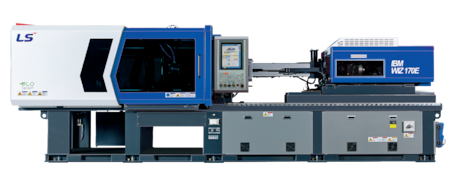

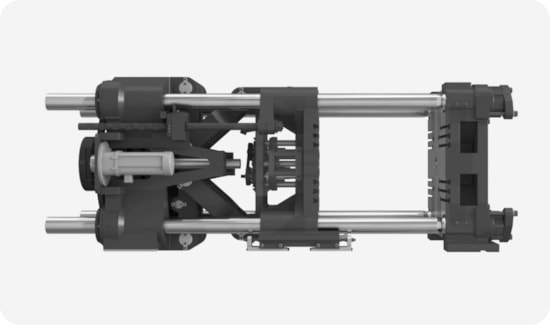

All-electric injection molding machine,

300–8.500 kN clamping force, toggle system

The WIZ-E Plus series is the result of many years of research and experience in the development and production of injection molding machines. These exceptional machines combine the advantages of servo-electric technology, an injection speed/pressure control algorithm, compliance with safety standards, a five-point articulated clamping system designed by FEA analysis and a high-speed injection mechanism.

Available tonage (t): 30, 50, 80, 110, 130, 170, 220, 280, 350, 400, 450, 550, 650, 850

Screw diameter: 16 - 115 mm

Injection pressure up to 3.000 bar

Injection speed up to 500 mm/s

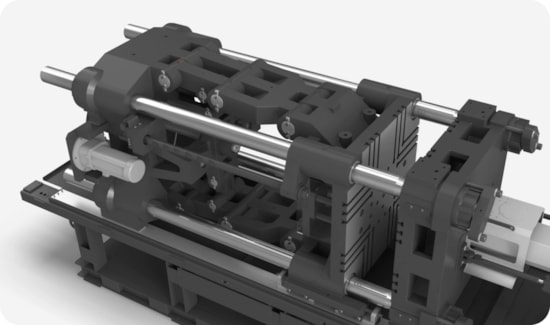

Extended mold opening distance

Extended by 3-20 % compared to existing products, providing efficiency through optimal design for various molds.

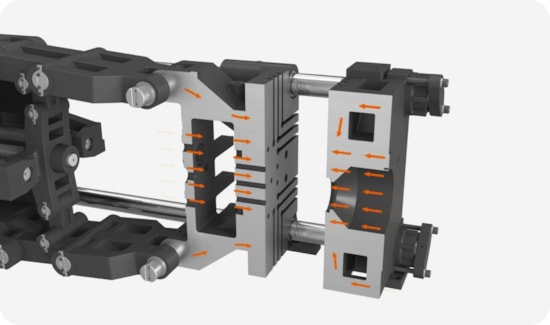

Improved mold life

Unified center press moving platen and Euromap ejector to enhace moldability of many cavity molds and minimize platen deformation.

High-strength center press platen

Applied high-center press platen to minimize platen deformation, improving the uniformity of mold pressure distribution.

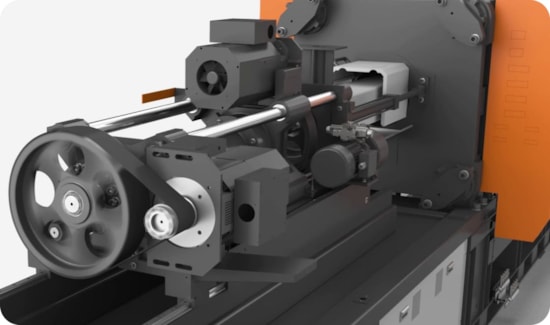

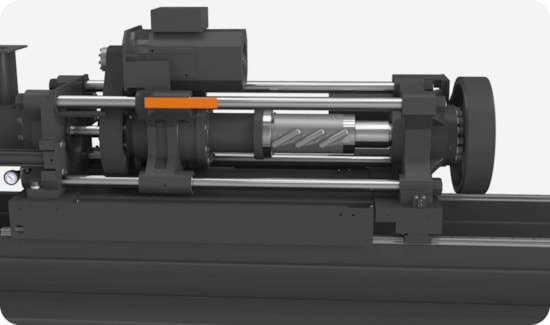

Outstanding injection speed response

Developed high-output, high-response dedicated injection servo motors, improving response time and control charakteristics for injection speeds up to 500 mm/s.

Energy monitoring and efficient management

The energy monitoring display enables easy monitoring and efficient management with simple operations.

Simultaneous operation with individual servo motor control

We have shortened cycle times and enhanced productivity by implementing simultaneous operations like metering during mold opening, ejection during mold opening, and injection during pressure building with individual servo motor control.