LS Mtron provides multi-shot injecton molding using LS Mtron's accumulated power-driven techniques to control injection volume, speed through multiple injection and digital precision control which injects two or more materials simultaneously or sequentially. In particular, it is possible to change and combine to suit the customer's needs, providing a customized solution to the special purpose customer, and transport it by axis or vertical rotation using the rotational function provided by the machine or mold.

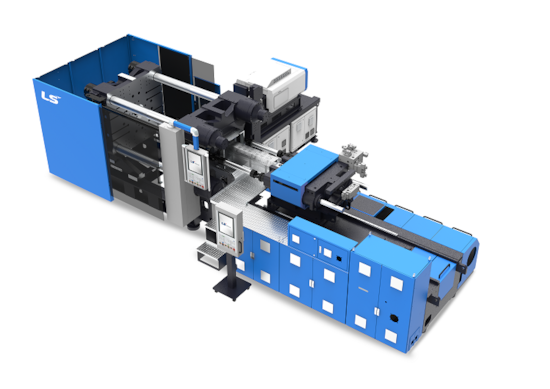

WIZ-EC (P version)

- Pneumatic stopper: Easy to replace the stopper and adjust the position of the taper stopper.

- Best-in-class rotating plate size: the largest gap between the tie bar in Korea and the extension of the length of the shape.

- Rotating plate servo motor drive: Reduce mold rotation time and improve positional precision with index units using AC server.

- Option: Application of ejector pin segmentation type(reduction of extraction time) / Application of magnetic plates

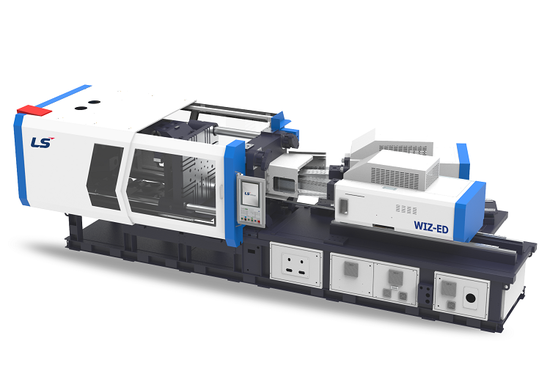

WIZ-ED

- Injection exclusively for LENS

- Large specifications of screws can be fitted to primary and secondary injection units

- Post-molded products by applying longitudinal pressure injection servo (maintenance time of more than 300 seconds)

- Transparent Dedicated Screw Design Applied

- Injection Precision Slow Control

- Reduce cycle time (2-layered molding)

- High-rigid center press plate applied

- Molding characteristics

- Secondary injection system can be installed without restricting injection volume

- Easy to switch into general injection(single product)

- Utilization of floor space is relatively efficient

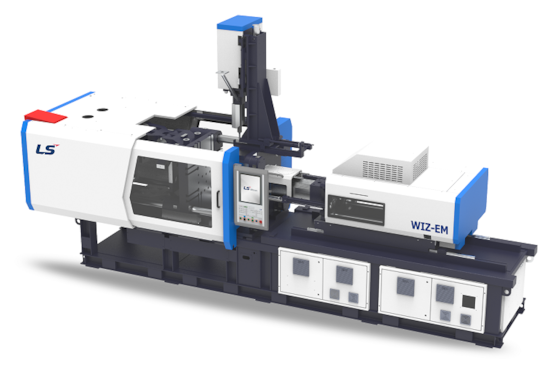

WIZ-EV (V version)

- Vertical structure of a two-liquid injection device: The injection device is mounted perpendicular to the top of the fixed plate and occupies the same space as the standard machine(high-cycle shape high speed application / high-digestion screw applied exclusively for packaging).

- Multi-layer technology applied: Technology that improves the formation of blocking layers(EVOHs) on the surface of the product through multi-stage injection.

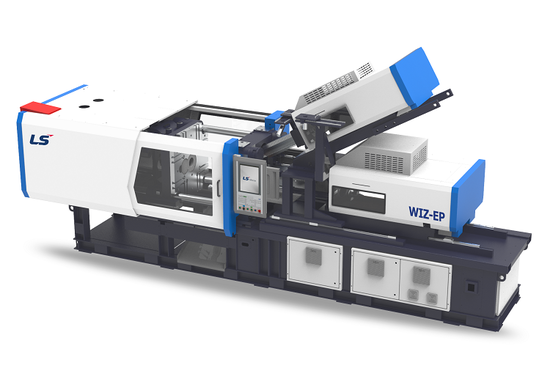

WIZ-EPR (R version)

- Molding characteristics

- The narrower the gap between the two nozzles, the more space between the four tie bars can be fully utilized to minimize the mold size

- Individual control of two injection units results in different injection sequences and increased molding precision

- European double injection molds or standard molds can be applied

- Core Turn

- By applying core turn(index core), 4 portable plates of servo motor injection molding machine are installed to implement individual and simultaneous operation

- Simplify mold structure and increase productivity

- Fast and accurate core rotation with servo precision control

WIZ-EL (L version)

- Mechanical structure

- Additional injection device is located on the semi-manipulated side(determined according to mold structure).

- A structure in which two gates are perpendicular to each other in two types of molds.

- 1st injection device: press + 2nd injection device power type.

- Scalability

- Applicable to existing injection machines or third-party injection machines

- Up to 5 additional injection devices can be attached