LSR injection,

1.100-2.800 kN clamping force, all-electric IMM WIZ-E series

Liquid silicone rubber is widely used in various industrial fi elds with its harmless property to humans (Non-toxic, colorless, odorless , and tasteless) and chemically stable property (ability to resist extreme temperatures, insulation, flame resisting, etc.). All-electric injection molding machines WIZ-E LSR Series provides a precise and efficient total solution to our customer with our accumulated technology (Auxiliary equipment and controlling technology for LSR injection and molding).

Mold

- Heated electrically or with fluid: temperature = 150~220℃

- Cold Runner: temperature = 23℃

- Hardened steel for cavities

- Vacuum

Injection Molding Machine

- Standard Injection Molding Machine

- Special Injection Unit: temperature = 23℃

- Optimized Non-Return Valve

- Control Pump and Handling

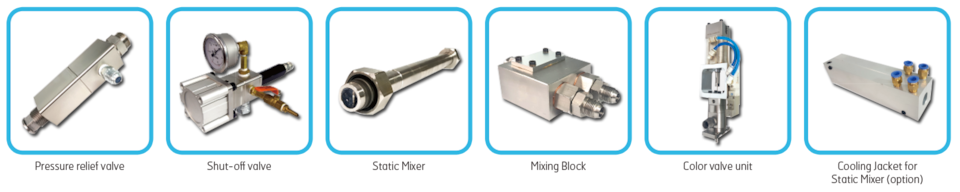

LSR Mixing Unit

- Pneumatic or hydraulic → SERVO MOTOR

- Material pressure ~200 bar → 60~80 bar

- Mixing ratio 1:1 additional color/additive line

- Static mixer and pressure reduction

Injection unit

- Special shut off nozzle (changeable nozzle tip)

- Plate type screw head Ass´y - Improving injection reproductivity

- Nozzle tip for cold Runner CRB (Cold Runner Block)

- Cooling Jacket Barrel - Reduction cycle time by precise temperature control