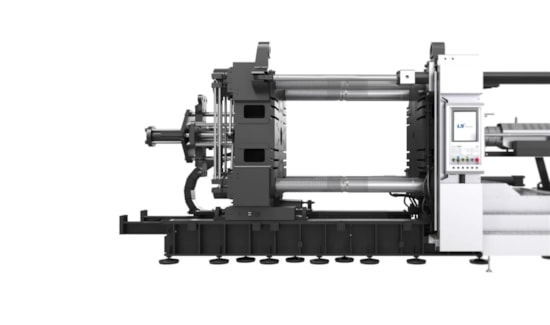

Hybrid injection molding machine,

4.500–32.000 kN clamping force, two-platen

WIZ Plus is a range of LS Mtron injection molding machines characterised by a two-platen clamping unit concept. This concept provides a large space for the mould and for the molding, while being very fast and energy efficient.

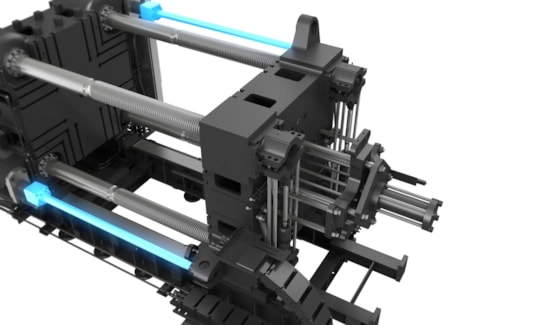

Booster cylinder structure improvement

Improved booster cylinder structure has increased mold opening and closing speed. Standardization is achieved, allowing for uniformity, with circular bearings making assembly and positional adjustment easy.

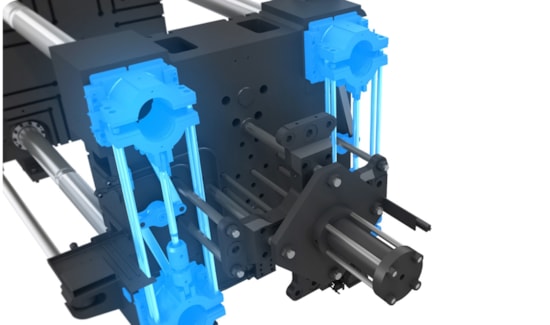

Quick mold clamping device

An integrated simultaneous operation reduces mold clamping time, improving cycle time and preventing half-nut jamming errors.

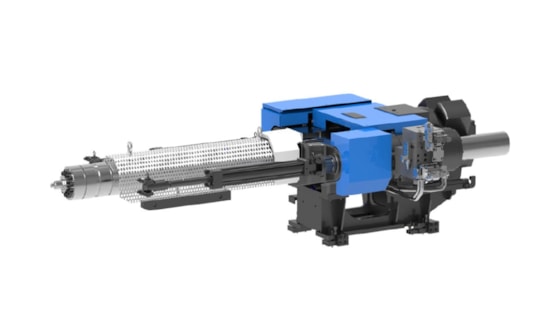

Injection unit structural improvement application

Structural improvements in the injection unit allow for easy replacement of Y, A and B screws. Changes can be made simply by replacing the barrel assy and adjusting the nozzle cylinder without the need for other replacements.

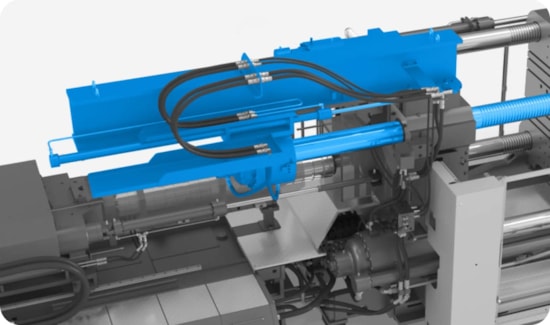

Tie-bar puller device (option)

Through one-touch operation the tie-bar can be easily separated, facilitating mold changes in spaces with low ceilings. This results in reduced investment costs compared to dolly equipment.

Heavy mold mounting

The design features long sliding supports and high-strength, optimized plates specifically for heavy molds, thereby enhancing the mounting and durability of such molds.

Application of KEBA controller

Increases convenience with an easy-to-understand user-centric UI. Real-time data setting, operation monitoring function, and other features make management effortless.