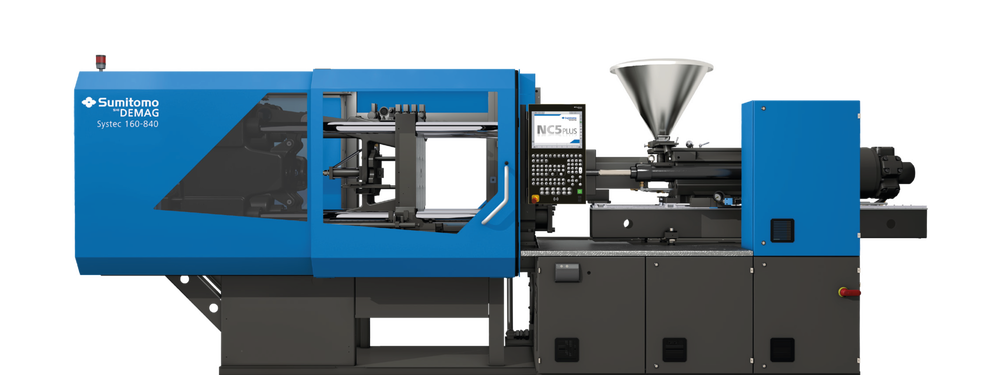

Maximum flexibility

highest reliability

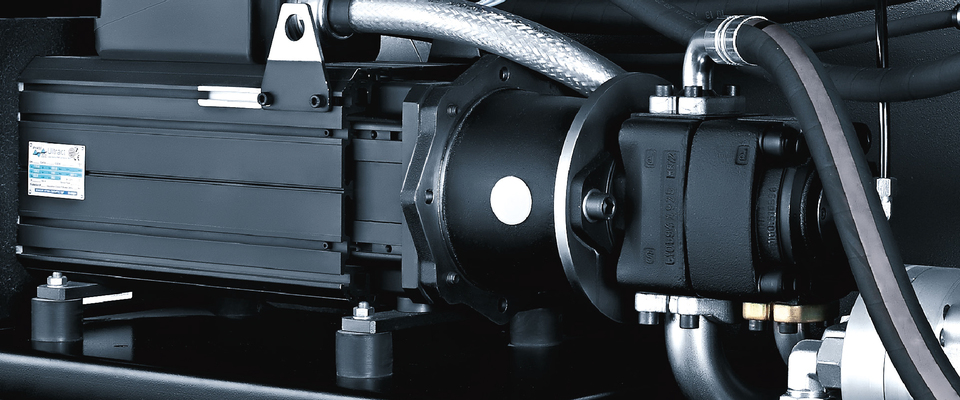

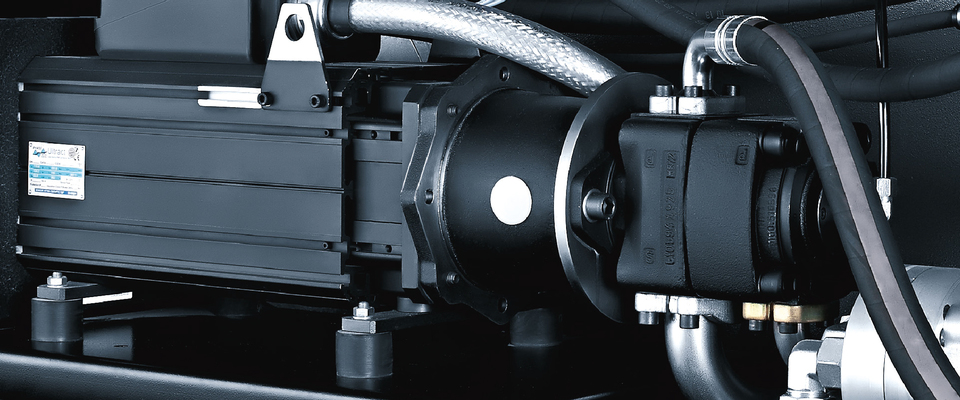

Servomotor drive

Due to the increasing demand to minimize energy consumption and noise emission, our Systec machines are equipped with servohydraulic drive technology as standard. The customers advantage is obvious, highest efficiency in connection with proven machine technology.

Toggle technology

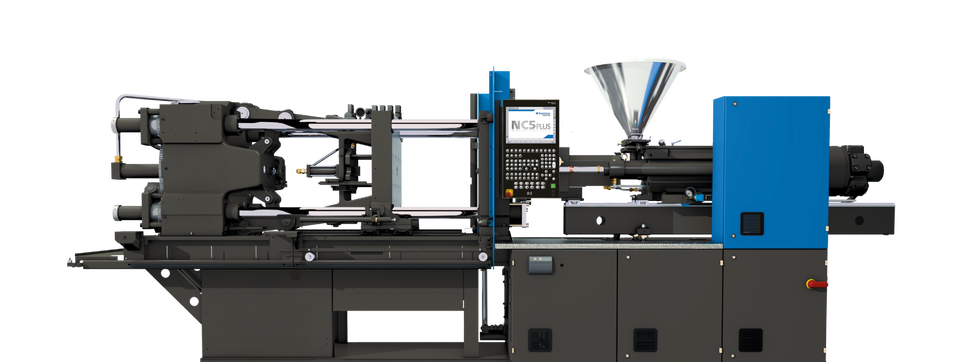

The Systec clamping unit is equipped with proven toggle technology.The special kinematics guarantee optimum mould movements, maximum plate parallelism and homogeneous force transmission into the injection mould. With the use of linear guides, effects such as tilting can be reduced and thus minimizes your mould wear even with high mould weights.

Intelligent drive technology

All the motion axes were analyzed and redesigned using state-of-the-art simulation software. The characteristics of the hydraulic elements have been precisely matched to the injection moulding process of the Systec machine. This leads to harmonious movements, high performance and a reduced noise level.

Intuitive control

The intuitive control of Systec offers a multitude of advantages for your staff. Visually clear, structured and efficient options for process monitoring and control help the user to quickly find the optimal settings. The logical and simple programming with predefined machine sequences serves to fully exploit the potential of Systec.

Efficiency Modules

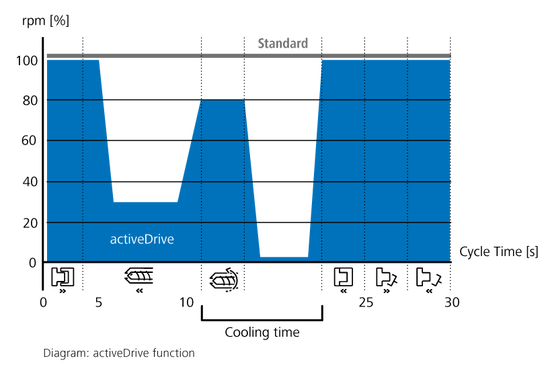

activeDrive

Save energy and therefore costs – activeDrive, the energy-saving drive system for Systec machines, guarantees maximum energy efficiency. During idle periods such as mould cooling or part removal, the intelligent drive throttles pump performance to provide hydraulic power only when needed. With this technology you save energy, costs and protect the environment.

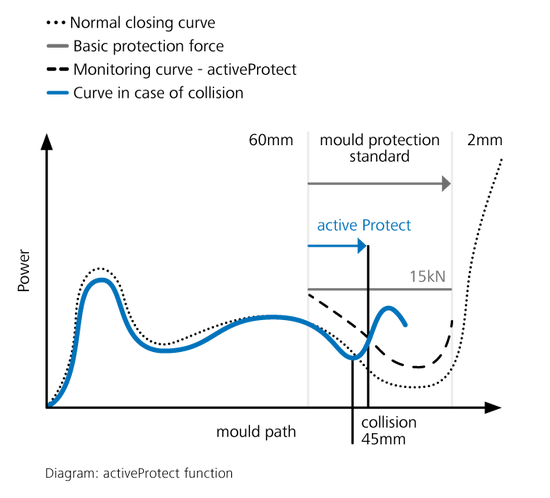

activeProtect

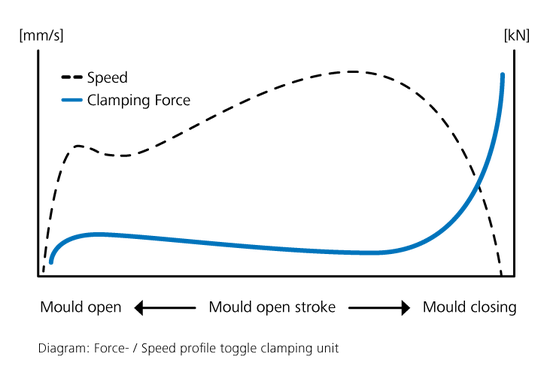

Protect your mould - With activeProtect, the integrated mould protection technology, a permanent profile monitoring of the mould movement is possible. The machine can react to even the smallest disturbances and the resulting deviations from the normal closing path. The monitoring can be used both for the mould closing movement and for opening the injection mould. With this technology, you also have the option of monitoring slide movements and thus optimally protect your mould.

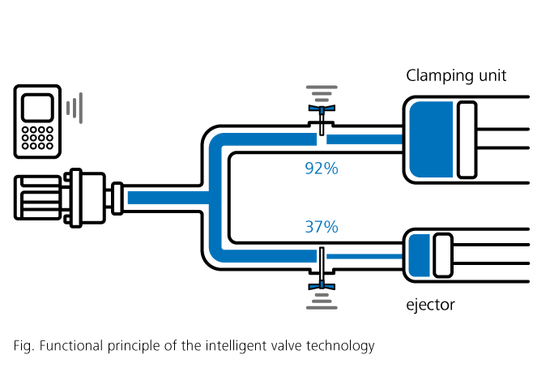

Intelligent technology

Intelligent valve technology

Due to specially developed valve geometries and special valve control, it is possible to have parallel movements with only one hydraulic circuit. Our customers confirm that despite the use of only one hydraulic circuit, parallel movements of the mould or ejector do not influence each other. Thus, Systec is able to realize a wide range of processes without the use of more expensive dual-circuit hydraulics. The result of this optimization is reflected in harmonious movements, higher injection dynamics, faster axis movements and a reduced noise level.

Toggle clamping unit

The toggle provides Systec with the optimum kinematics for mould movement in the injection molding process. Due to the high dynamics during acceleration, the low power requirement during the process and the optimal closing force build-up during platen contact, the motion sequence of the mould closing process can be perfectly represented. The special kinematics allow up to 30% faster mould movements than direct hydraulic clamping units and guarantee optimum process times. Finally, the high forces when opening the mould ensure that the process is stable and safe. Robust, low-maintenance and optimal kinematics - the perfect technology for your production.