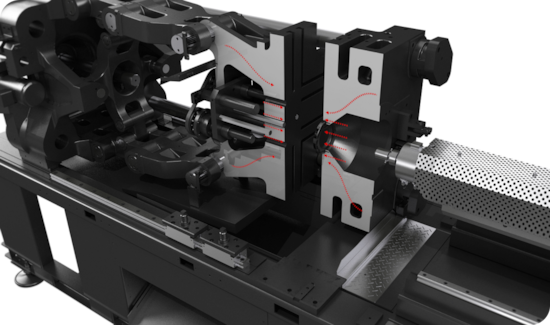

Premium all-electric injection molding machine,

500–4.000 kN clamping force, toggle system

The premium all-electric IMM of theONE-E series is a compact energy-efficient machine with high-precision injection moulding. With it, LS Mtron responds to rapidly changing market trends, the demand for increasing product specifications and technological excellence. In doing so, it accurately reflects the needs of customers and increases their satisfaction by expanding the range through a diverse product range.

Available tonage (ton): 50, 80, 110, 130, 170, 220, 280, 350, 400

Screw diameter: 22 - 70 mm

Injection pressure up to 2.800 bar

Injection speed up to 500 mm/s at all models

Dry cycle from 1,07-252 (sec-mm)

Mold acceleration (standard)

Applied high-speed pulley ratio to achieve high-cycle and upgraded the mold motor capacity.

Minimum/maximum mold thickness (standard)

Reduced mold minimum thickness and increased maximum mold thickness, enhancing ease of handling for various mold injections.

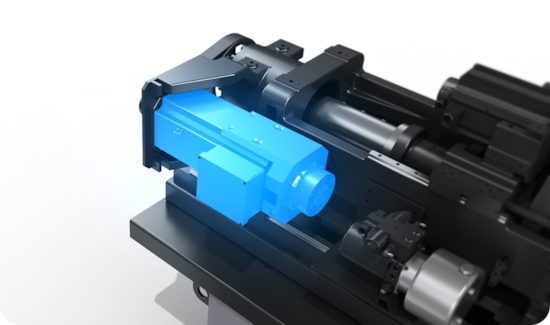

Extrusion stroke speed (standard)

Extended extrusion stroke and increased extrusion speed, implementing an optimized extrusion process.

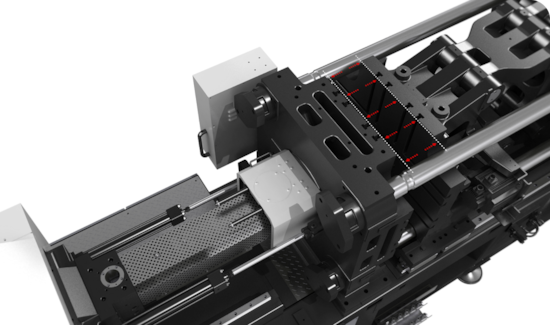

High-speed toggle system (standard)

Enhanced link speed ratio and reduced impact from low-vibration operation, thus shortening dry cycle times.

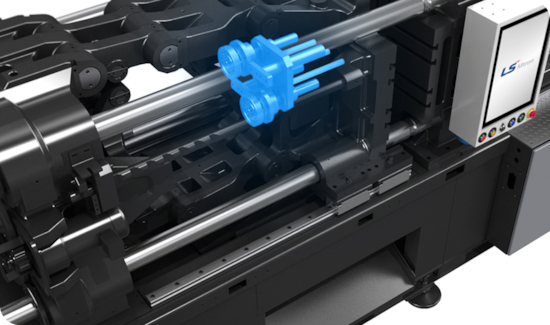

Center press fixed platen (standard)

Minimized platen deformation, suppressing cavity deviations, thereby improving mold pressure distribution and extending mold life.

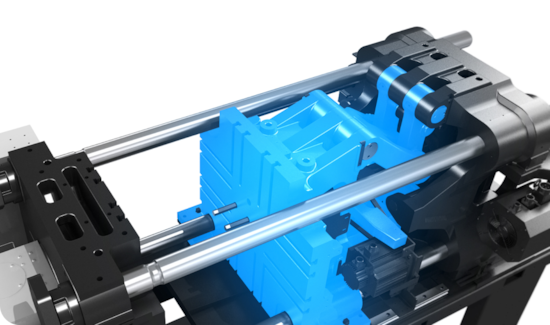

Moving platen LM guide support structure (standard)

A low-friction structure anabling fast mold open/close action, ensuring precise platen parallelism and position control.